You are here

Membrane Circuits

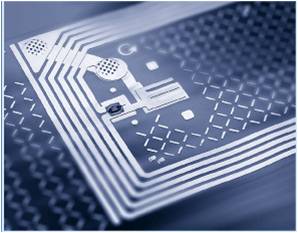

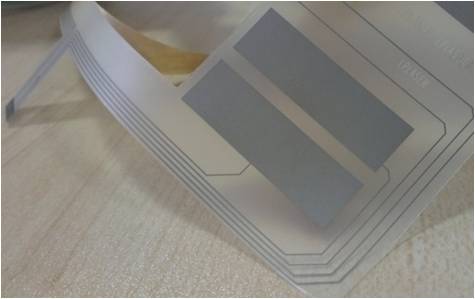

RFID & NFC Antenna

1.Silver paste print circuit ,UV insulation ink protect finished

2.Can chose PET/paper base material

3.Roll to Roll printing and reliable production process control ,can reduce customer’s cost and offer convenience for STM die placement in later period .

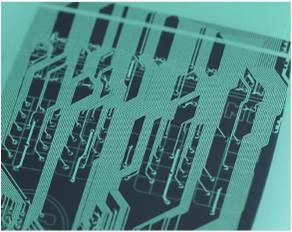

E-paper displays the circuit of back board

1.Silver paste/Carbon ink/Silver mixed with Carbon printing circuit

2.PETbase material thickness: 0.075mmm, 0.1mm, 0.125mm, 0.188mm

3.Souble-side printing circuit, connect positive and negative circuit by tiny hole conduct

4.Min line width:0.15mm

5.Min space:0.15mm

6.Min hole diameter:0.2mm

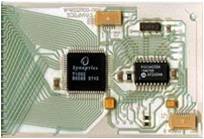

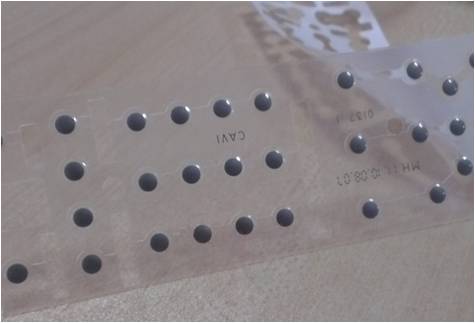

Membrane circuit with SMD components

1.Silver paste print circuit ,UV insulation ink protect finished

2.Can chose PET/paper base material

3.Can chose double-side printing circuit, so will leave more space for SMD placement

4.Assemble components by using reliable low temperature conductive splice

5.SMD components type: Diode, Resistor, Capacitance, IR Sensor and so on

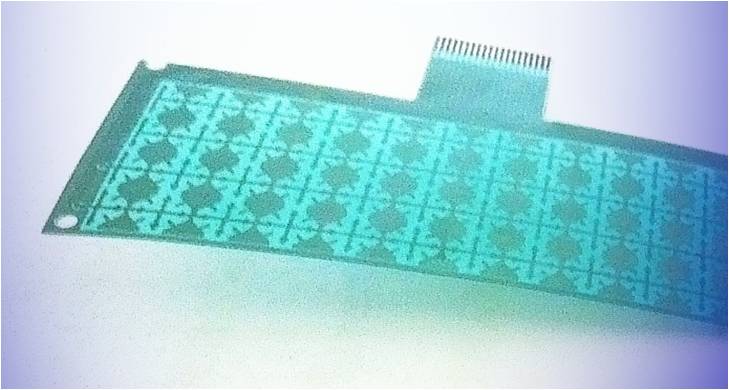

Capacitive touch screen membrane circuit

1.Silver paste print circuit ,UV insulation ink protect finished

2.Can chose PET/paper base material

3.Using double-side printing , XY in the both side of membrane, positive and negative circuit using tiny hole breakover(the min diameter of hole is 0.2mm)

4.Reliable anti-electromagnetic protection design, maximum protect low rate of circuit from wrong operation when use .

5.100% test before leave factory ,include connection test, short circuit test and sensitivity test (can set the sensitivity according to request when test) ,Make sure the defective rate below 500ppm .

Various game console controller membrane circuit

1.Silver paste print circuit ,UV insulation ink protect finished

2.Can chose PET/paper base material

3.Can set key’s resistance according to design(High resistance).Resistance can control within +/-10%

4.Unique high resistance carbon ink control craft.

5.100% test conduction, short circuit and resistance before leave factory . High speed multi imposition automatic test system ( resistance, key function, defective mark) solved bottlenecks in the process of testing production

Capacitive keyboard membrane circuit for home appliance

1.Silver paste print circuit ,UV insulation ink protect finished

2.Transparent PET base material

3.Can chose transparent conductive ink (a little slight blue),with this ink can effective enough to ensure the rate of light transmittance above 85%.Compared with the transparent circuit produced by etch , it has enormous advantage forenvironmental protect , low resistance and save cost

4.Adopt high speed(2S / pcs) adjustable sensitivity test system,100% test ON/OFF and sensitivity , it has on line advantage compared with other same trade who only test ON/OFF

POLY-DOME Membrane Circuit

1.Silver paste print circuit ,UV insulation ink protect finished

2.Transparent PET base material

3.High speed roll to roll printing ,make sure the stability and consistency of resistance and size when printing

4.High speed roll to roll embossing, eradicate the high temperature affect product because of taking material when semi-automatic embossed.

5.Adopt numerical control carved mold, eradicate the difference of hand feeling between keys and keys when produce with handwork cared mold

Membrane circuit for writing board

1.Silver paste print circuit ,UV insulation ink protect finished

2.Transparent PET base material

3.can chose structure of single multi layer or double multi layer (Min dia of hole is 0.2mm)

4.Min line distance 0.3mm,thickness line space 0.18mm

5.Adopt numerical control carved mold, eradicate the difference of hand feeling between keys and keys when produce with handwork carved mold